Your global partner for cemented carbide components in China

Jade has extensive experience in producing thousands of custom carbide grinding rod, ensuring your project benefits from efficiency, precision, cost-effectiveness and fast delivery.

company introduction

Zhuzhou Jade was established in 2016 and is located in Zhuzhou City, Hunan Province, China. It has a processing and R&D workshop of about 2,000 square meters. The company is committed to the professional research and development and production of cemented carbide grinding rod, molds and wear-resistant parts, providing overall solutions including various types of cemented carbide cutting tool blanks, non-standard special-shaped key parts of shafts and related products.

Start today. Get parts made fast.

Top China carbide cutting tool precision blank customization service

Applications of Cemented Carbide

Tungsten steel ball valve, valve stem, valve seat

Tungsten steel ball valve, valve stem, valve seat

Precision ceramic parts

Precision ceramic parts

What makes Jade Co., Ltd., Different?

Over the past decade, Jade has accumulated extensive expertise in carbide machining.

As a custom carbide grinding rod manufacturer, Jade boasts diverse production facilities and capabilities to meet your diverse and growing needs.

With our extensive production capabilities, you can always find the carbide grinding rods you need online.

10% better prices than the average market

80 % Percent Repeat Orders By Clients Procured Material from us

Conduct strict quality inspection for each batch of products.

Solid after-sales customer support policy.

PRICE

DELIVERY TIME

SHIPPING COST

DESIGN COST

CUSTOMER RETENTION

RESPONSE TIME

How to process cemented carbide precision ground rods?

CNC High-precision centerless grinder

High-precision centerless grinder

High-precision centerless grinder

Three-coordinate measuring

Three-coordinate measuring

Surface Finishing

High-Yield Manufacturing Services Across All Industries.

Why choose us

Quality

We guarantee each unit within a specified tolerance and use only the best materials.

Reliability

You can count on us to get the job done on time, right, every time, and for a price you can afford.

Precision

Precision machining that means you can pass along excellence to your customers.

Our Domestic And International Sales Market

We provide you with carbide precision ground rods to start your project faster with less risk and lower cost.

Powerful Capabilities

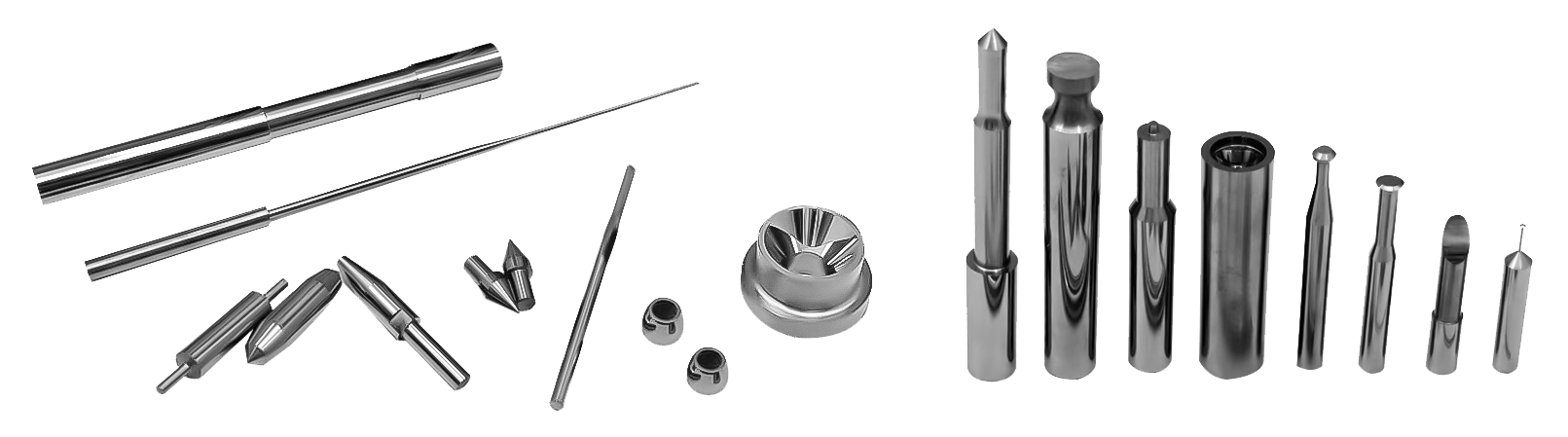

Tungsten steel grinding head

Tungsten steel grinding head

Tungsten steel grinding head

ungsten steel mold core rod

ungsten steel mold core rod

ungsten steel mold core rod

Frequently Asked Questions

CNC cutting tools are tools specifically designed for cutting operations on CNC machine tools. Compared to traditional machine tool tools, they require higher precision, durability, and stability to adapt to automated, high-speed, and high-precision machining processes.

The carbide precision grinding rod cost depends on many factors and varies among different situations.

The material is a big factor.

The design complexity also makes a difference in the CNC machining cost.

It’s easy to understand that the more complex the design is, the more machining process is required and the higher the price will be.

Other factors such as market fluctuation and the order quantity can also affect the final quotation.

If you want to know the carbide precision grinding rod cost for your project, send us a message and you will receive a quotation with manufacturing advice within 24 hours.

Didn't find answer of your question?